Charpy impact testing.

TESTING METALS AND METAL COMPONENTS FOR CRITICAL ENGINEERING APPLICATIONS.

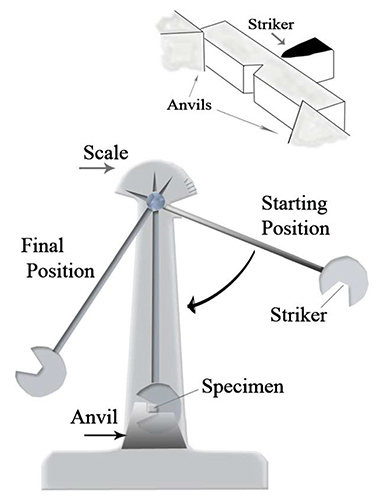

Charpy Impact Testing measures the amount of energy absorbed during fracture of a specimen to determine its Ductile to Brittle Transition Temperature (DBTT), which can be graphed in our report. Testing includes sample preparation of three specimens per test and is used primarily for steels which exhibit temperature dependent behavior relating to toughness of the material at high strain. This toughness is typically related to direction of the rolling or grain flow of a forging. Materials are usually tougher along the direction of rolling and not as tough across the direction of rolling.

Charpy Impact Testing measures the amount of energy absorbed during fracture of a specimen to determine its Ductile to Brittle Transition Temperature (DBTT), which can be graphed in our report. Testing includes sample preparation of three specimens per test and is used primarily for steels which exhibit temperature dependent behavior relating to toughness of the material at high strain. This toughness is typically related to direction of the rolling or grain flow of a forging. Materials are usually tougher along the direction of rolling and not as tough across the direction of rolling.

This type of testing is often specified in welding codes for pressure vessels, valves and fittings used in the oil and gas industry, related piping, pipelines, outdoor structures, hi-rise buildings, towers, bridges, agricultural vehicles, industrial equipment, and other critical building, infrastructure, and engineering applications.

As an independent, accredited mechanical test lab, Charpy Impact Testing is conducted at ATRONA on a daily basis per ASTM A370/E23. ATRONA has two high capacity pendulum impact testers and employs state of the art sample preparation and testing methods. Part size does not matter. Hardness of the part does not matter either. Our capabilities include 16 cutting machines ranging in size from high speed diamond saws to a very large double column band saw that can cut 40" by 40" part. All saws are capable of cutting hard materials with carbide blades.

Specimens needed for Charpy Impact Testing are normally cut from the actual part or weldments using an abrasive cut off saw or a band saw with low heat input. Base metal specimen is 55 mm (about 2.25" inches) in length, 10 mm thick and 10 mm wide. Centerline of the Charpy specimen is notched according to standard with a special broach to create the required V-Notch with the appropriate dimensions and surface finish. Sub-size specimens can be made with 7.5 mm x 10 mm or 5 mm x 10 mm or 2.5 mm x 10 mm. Threaded fasteners and pipe have special considerations. Specimens are tested either at room temperature or at a specified temperature, such as -20ºC, -10ºC, 0ºC, +10ºC, +20ºC.

Specimens needed for Charpy Impact Testing are normally cut from the actual part or weldments using an abrasive cut off saw or a band saw with low heat input. Base metal specimen is 55 mm (about 2.25" inches) in length, 10 mm thick and 10 mm wide. Centerline of the Charpy specimen is notched according to standard with a special broach to create the required V-Notch with the appropriate dimensions and surface finish. Sub-size specimens can be made with 7.5 mm x 10 mm or 5 mm x 10 mm or 2.5 mm x 10 mm. Threaded fasteners and pipe have special considerations. Specimens are tested either at room temperature or at a specified temperature, such as -20ºC, -10ºC, 0ºC, +10ºC, +20ºC.

ATRONA offers competitive prices and fast turnaround times for Charpy Impact Testing.