Microstructure evaluation.

WE'VE TAKEN MICROSTRUCTURE ANALYSIS TO A NEW LEVEL AT ATRONA.

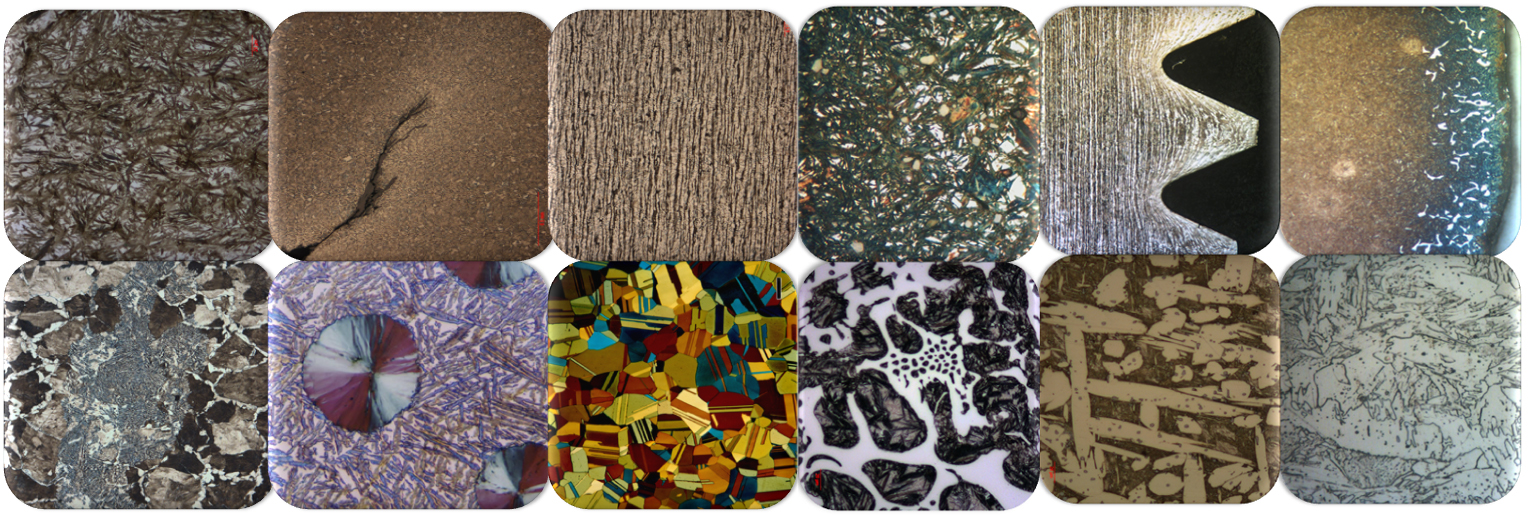

Most metals at different stages of their processing life and heat treat conditions exhibit a specific microstructure that can be evaluated to see if: the material was heat treated as required; to investigate if the raw material was processed and produced per quality standards; or to simply find out why a material is not responding to specific applications or machining operations. Microstructure can also be used to predict tool life or even the performance of a particular part, since it can be used to reveal specific properties, such as strength, ductility, corrosion resistance, and other conditions and properties. Finally, it can be used to help assess the quality of a specific heat treater or raw material supplier.

Advanced equipment and capabilities

At ATRONA Test Labs, we’re microstructure evaluation experts. Utilizing a range of proprietary methods and techniques, along with state-of-the art lab software and equipment, including a new Keyence VHX-5000 Digital Microscope, we’ve taken microstructure evaluation and analysis to a new level. Our new next-generation microscope has a large depth-of-field and advanced measurement capabilities for inspection of metallurgical or other specimens, as well as failure analysis. It lets us observe any area of the sample completely in focus with real-time depth perception and 3D high resolution HDR imaging capability; so, we can analyze the topography or view it from any angle with magnification up 5000x. These images can then be captured and saved, and/or measured directly on the screen. This device also utilizes advanced image stitching technology which gives us an overall view of the target at high resolution (up to 20,000 by 20,000 pixels) in real time.

At ATRONA Test Labs, we’re microstructure evaluation experts. Utilizing a range of proprietary methods and techniques, along with state-of-the art lab software and equipment, including a new Keyence VHX-5000 Digital Microscope, we’ve taken microstructure evaluation and analysis to a new level. Our new next-generation microscope has a large depth-of-field and advanced measurement capabilities for inspection of metallurgical or other specimens, as well as failure analysis. It lets us observe any area of the sample completely in focus with real-time depth perception and 3D high resolution HDR imaging capability; so, we can analyze the topography or view it from any angle with magnification up 5000x. These images can then be captured and saved, and/or measured directly on the screen. This device also utilizes advanced image stitching technology which gives us an overall view of the target at high resolution (up to 20,000 by 20,000 pixels) in real time.

Pictured above: Photomicrographs taken at ATRONA of various microstructures of ferrous and non-ferrous metals.

Our metallurgical lab also has four fully-equipped Metallographs with full image analysis capabilities utilized for microstructure examination. For steel mills, fabricators, machine shops, and other high-volume clients, our automatic stage microscopy and image analysis enable us to accurately analyze up to eight specimens simultaneously - saving you both time and money. So, if you are looking for grain size, banding classification, simple phase analysis, or raw material cleanliness (inclusion ratings), call us for a quote.

Grain size measurement can be part of a more extensive microstructure examination or it can be conducted by itself as an inspection tool after a forging operation, a heat treat operation, a rolling operation, etc. Typically, the finer the grain size the better the material condition. Most alloy steels require ASTM 5 or finer grain size and some tool steels require 10 or finer grain size.

In addition, we can also determine grain boundaries, nodularity, phase percent, particle size, dimensional measurements, coating thickness, retained austenite rating, morphology, cast iron graphite analysis, spheroidization analysis, rolling direction, carbides analysis and distribution, ETA phase analysis, surface condition and grinding effect, microporosity analysis, percent phase (pearlite, ferrite, bainite, martensite, etc.), cementite, steadite, carbides in any material, tempered or untempered martensite, as well as non-ferrous materials. We also perform microstructure analysis on stainless steels of all grades including corrosion-resistant steels, heat-resistant steels, magnetic and non-magnetic, and high-strength stainless steels. And all at some of the most competitive prices in the industry.