Mechanical testing.

DETERMINE THE MECHANICAL PROPERTIES OF METALS AND OTHER MATERIALS, FASTENERS, WELDMENTS, AND MORE.

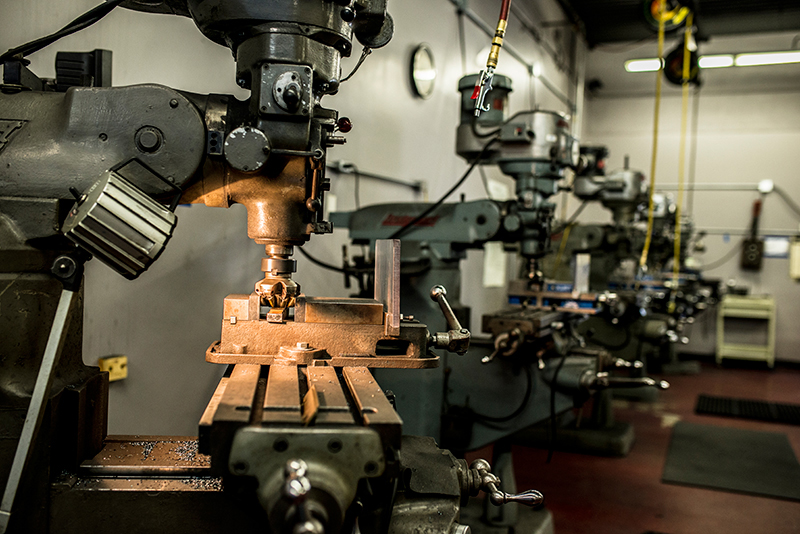

At ATRONA, we offer a range of mechanical tests, including Charpy impact, tensile, compression, shear strength, torque measurement, proof load, and much more. Part shape and size hardly matter with our extensive sample preparation capabilities. Our machine shop has equipment ranging from small high speed diamond saws to double column band saws with carbide blades, as well as mills, and lathes (manual and CNC), for fast, expert machining of test samples to the applicable standard.

Mechanical tests we conduct daily include:

CHARPY V-NOTCH IMPACT TESTING to test metals and metal components used in critical engineering applications. Testing includes sample preparation of three specimens per test and is used primarily for steels which exhibit temperature dependent behavior relating to toughness of the material at high strain.

FASTENER TESTING - Any type, any grade. Whether you’re evaluating raw materials, quality issues with production, finished products, or just suppliers, we can provide you with the test data you require to make informed and timely decisions. Mechanical tests we conduct for fasteners include tensile testing, torque measurement, proof load testing, shear strength testing, and much more.

SALT FOG CHAMBER to determine how your metal parts or components will stand up to the elements. Tests include salt spray/salt fog testing, high and low temperature testing, chemical exposure testing, and other environmental custom type testing.

TENSILE TESTING to determine the strength and ductility of a material, determine batch quality, or assure compliance with provided mill certs or industry standards. This test generates a Stress Strain Curve showing how the material reacted when linear force was applied (providing yield strength, elongation, etc.).