Weld verification and analysis.

Minimizing the risk of failed welds.

Welding is considered a special process and an essential element in many manufacturing and fabrication processes; as well as a vital tool to maintain assets in industries ranging from Oil & Gas to Chemical Processing and from Building to Transportation.

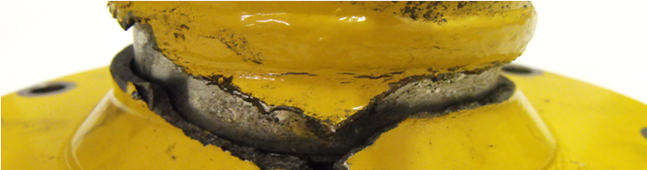

Unfortunately, welds can fail. And that means costly downtime or rework at a minimum. In a worst-case scenario, that defective or failed weld can cause harm to life and property.

A weld testing and analysis plan or protocol can help you minimize this risk. At ATRONA Test Labs, we can verify that welds have the strength, hardness, ductility, or other material properties required for their intended application per your specification or standard quality procedures before that part, component, equipment, or production lot, is put into service. Weld analysis can also be used to compare and contrast different weld samples; or two or more suppliers, two or more processes, two or more operators, two or more welding methods, or even a new design or procedure versus an old one.

FAILED WELD RISK FACTORS

It’s important to realize that there are many factors that can lead to a failed weld. Causes can range from equipment failure or human error (porosity, lack of fusion, excessive spatter, concave or convex weld bead, crater cracks, lack of weld joint penetration, adhesion issues, shrinkage issues, heat affected zone, or HAZ, and excessive hardness, etc.) to process failures, such as hydrogen induced cracking (HIC) and even hydrogen embrittlement. In addition, the welding process itself can inadvertently weaken parts or equipment by imparting residual stresses into a material thus contributing to reduced material properties.

At ATRONA, weld analysis is conducted using state-of-the-art technology and instruments, and expert staff. We offer both non-destructive methods (NDT) and destructive metallurgical testing to verify welds or determine the root cause of a failed welded part or component.

NDT methods that preserve the sample being tested include magnetic particle inspection (MPI) to reveal surface cracks and indications; visual and stereoscopic analysis with high resolution photography to reveal surface discontinuities and surface irregularities; and liquid dye penetrant analysis to reveal surface indications.

Destructive metallurgical testing is often used for weld sampling plans and weld failure analysis investigations. This process includes sectioning through the weld to extract a representative specimen. This specimen is then mounted and polished to a mirror finish using an automatic mounting press and automatic multi-step polisher. Then, the weld cross section is examined utilizing advanced microscopic image analysis and microhardness testing with automatic stage and image mapping capabilities to capture a full mosaic view of the entire weld. Microhardness mapping of the weld can be performed to determine weld properties, HAZ properties, and the effect of the weld on the base metal.

Other analysis performed on welds includes mechanical testing. We can assess your weld through mechanical testing by tension, compression, bending, or torsion. We can also perform toughness analysis using Charpy impact v-notch testing to determine the toughness of the weld. Strength and toughness of welded joints can reveal crucial properties and the effect of welding on the actual weld, the HAZ and the base metal.

We're welding metallurgy experts.

Welding metallurgy is a complete science that not only deals with welding equipment, shielding gas, weld wire composition and size, and design of the weld groove but also with the chemical composition and condition of the components that need welding. It requires design and investigation for determining Carbon Equivalent (CE) values to know when to add pre and post heat to the welding process.

If your company uses welded parts or components, ATRONA would welcome the opportunity to work with you to develop an ongoing, cost-effective weld sampling plan or test protocol that will achieve your specific performance and quality goals within any budgetary constraints. We’re also experts in the field of weld failure analysis. In either case, we’re confident you’ll appreciate our concise reporting style with clearly written explanations, supporting data and tables, and quality photos and photomicrographs. Our expertise extends to many different types of welding techniques including: MIG, TIG, Submergible ARC, ARC, Electron Beam, Spot, Electrical Resistance, Friction, Inertia, and even micro welding (cold welding).

If your company uses welded parts or components, ATRONA would welcome the opportunity to work with you to develop an ongoing, cost-effective weld sampling plan or test protocol that will achieve your specific performance and quality goals within any budgetary constraints. We’re also experts in the field of weld failure analysis. In either case, we’re confident you’ll appreciate our concise reporting style with clearly written explanations, supporting data and tables, and quality photos and photomicrographs. Our expertise extends to many different types of welding techniques including: MIG, TIG, Submergible ARC, ARC, Electron Beam, Spot, Electrical Resistance, Friction, Inertia, and even micro welding (cold welding).